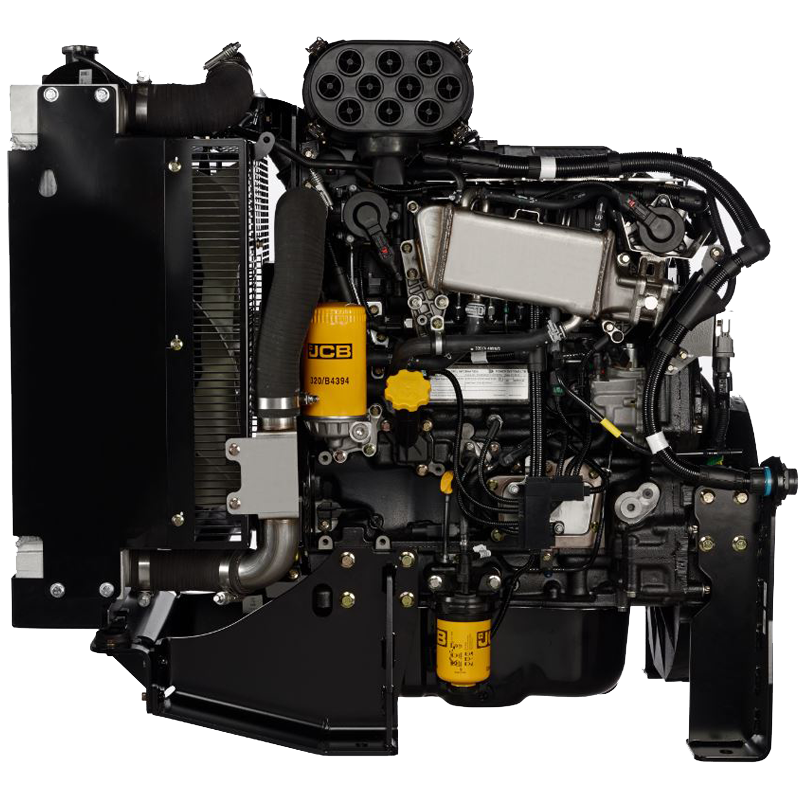

The JCB ECOMAX range of engines is ideally suited to construction, agricultural and materials handling applications which need to meet the latest emissions legislation.

In addition, we can still supply the JCB DIESELMAX engine range for power generation and marine propulsion applications as well as emerging markets where the emissions legislation is not so stringent.

Available now to meet the latest European Stage V emissions requirements aswell as the current EPA Tier 4 Final for the USA & other EPA controlled territories.

We can supply base engines, standard industrial IPUs or bespoke builds to OEM’s requirements.

All JCB DIESELMAX engines meet either European Stage 2 & 3A or EPA Tier 2 & 3 emissions requirements.

We can supply base engines, standard industrial IPUs or bespoke builds to OEM’s requirements.

DIESELMAX engines are supplied to meet Stage 2 / Tier 2 from 63kW to 212kW and Stage 3A / Tier 3 from 63kW to 120kW. All engines up to 93kW output feature mechanical governed fuel systems whilst higher power outputs utilise electronic high pressure common rail fuel systems.

We can supply a comprehensive range of JCB G-Drive base engines or IPUs for power generation applications with emissions compliances to European Stage 2, Stage 3A and now Stage V. The full range covers the power band from 50kVa to 200kVa, depending on emissions compliance level.

The JCB ECOMAX range are all 4 cylinder units with the following outputs;

The JCB ECOMAX range of engines is the natural progression from the technically acclaimed and highly successful Dieselmax.

In order to meet new legislation as well as their own requirements and those of other OEMs, JCB’s engineers redesigned the combustion process within the engine to achieve a cleaner burn and ultimately cleaner emissions out of the engine. This has resulted in the latest Stage V engines having a very compact exhaust after treatment system which can be mounted on the engine itself in IPU formats providing OEMs with a very compact and simple package to install.

The key benefits to JCB as a machine builder in their own right are also relevant to OEMs and end users adopting the JCB ECOMAX engines in their machines. Such benefits include smaller package size, reduced installation complexity, reduced fuel consumption and routine maintenance free exhaust after treatment.

Typical applications for the JCB range of engines include;

Crushing & Screening

Pumping – Irrigation & de-watering

Marine

Geotechnical Surveying

Materials handling

Airport Ground Support Equipment

Gen set

Zone II offshore flame protected

Vacuum excavation

Agriculture

Road planing

| Model | Power Rating | Rated Speed |

|---|---|---|

| 430TCAE55 | 55kW / 74HP | 2200rpm |

| 448TCAE81 | 81kW / 108HP | 2200rpm |

| 448TCAE97 | 97kW / 130HP | 2200rpm |

| 448TCAE112 | 112kW / 150HP | 2200rpm |

| 448TCAE129 | 129kW / 173HP | 2200rpm |

| Model | Power Rating | Rated Speed |

|---|---|---|

| 430TCAE55 | 55kW / 74HP | 2200rpm |

| 444TC55 | 55kW / 74HP | 2200rpm |

| 444TCAE68 | 68kW / 91HP | 2200rpm |

| 444TCAE81 | 81kW / 108HP | 2200rpm |

| 444TCAE93 | 93kW / 125HP | 2200rpm |

| 448TCAE108 | 108kW / 145HP | 2200rpm |

| 448TCAE129 | 129kW / 173HP | 2050rpm |